On demand manufacturing services have become an essential solution for businesses seeking flexibility and efficiency in production. Especially in industries requiring precision parts, these services allow manufacturers to respond quickly to market demands and customer needs, while also reducing lead times and minimizing inventory costs. Livepoint Tooling provides on demand manufacturing solutions that specialize in precision mold making, making it possible for companies to produce parts that meet strict quality and dimensional standards consistently across different production volumes. But what do these services actually do, and why are they increasingly relied upon in modern manufacturing?

Understanding the Core Functions of On Demand Manufacturing

At its core, on demand manufacturing enables production in response to specific orders rather than maintaining large inventories. This approach is particularly valuable for companies that need high-precision plastic molding, like Livepoint Tooling, as it allows for flexibility across the production cycle. One critical function of on demand manufacturing services is their ability to handle a wide range of production volumes, from prototypes to full-scale production runs. By offering rapid prototyping and iterative design adjustments, these services help manufacturers shorten product development timelines while maintaining high-quality standards.

Another key function involves simplifying supply chain management. Companies using on demand manufacturing services can reduce overhead costs by producing parts only when required. This decreases storage needs, minimizes waste, and improves overall operational efficiency. Manufacturers can adjust production schedules according to real-time demand, ensuring that inventory levels align closely with market needs, which is particularly important for sectors like automotive, consumer electronics, and medical devices.

Advantages for Precision Mold Manufacturing

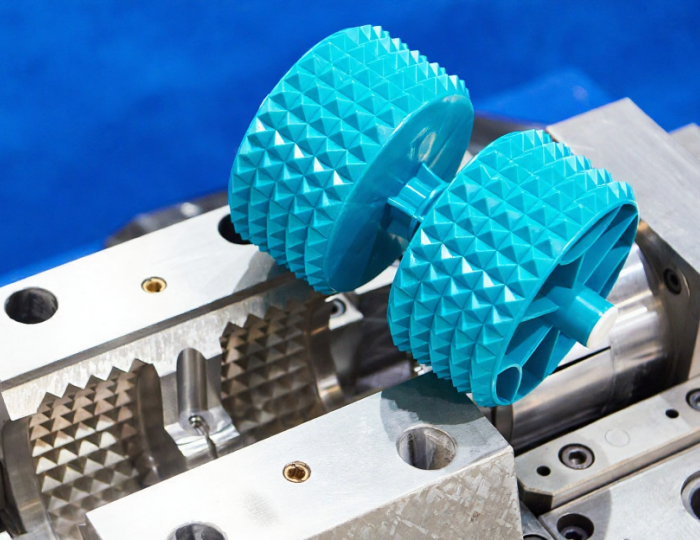

For precision mold manufacturing, the benefits of on demand manufacturing are substantial. By collaborating with providers like Livepoint Tooling, manufacturers can access plastic injection molding services capable of producing parts of all sizes with consistent quality and tight tolerances. This includes small-scale prototypes as well as larger batch productions. The ability to quickly adapt mold designs and maintain precise tolerances ensures that final components integrate seamlessly into assemblies, reducing the risk of errors and production delays.

Furthermore, on demand manufacturing services facilitate cost efficiency in high-precision molding projects. Since production occurs only as needed, companies can avoid the financial risks associated with overproduction and inventory holding. By leveraging advanced mold-making techniques, Livepoint Tooling ensures that even complex parts meet stringent specifications. This combination of precision, adaptability, and efficiency underscores why many manufacturers are increasingly turning to on demand manufacturing for their production needs.

Conclusion: Leveraging On Demand Manufacturing for Efficient Production

In summary, on demand manufacturing services provide essential functions and advantages for manufacturers, especially those engaged in precision mold production. They offer the flexibility to produce parts as needed, reduce inventory costs, and support rapid prototyping and iterative development. Companies like Livepoint Tooling, specializing in high-precision plastic molding, are able to deliver components that meet tight tolerances and maintain consistent quality across production volumes. By integrating these services, manufacturers can achieve efficient, adaptable, and reliable production processes while minimizing waste and ensuring high-quality outcomes. Ultimately, on demand manufacturing helps businesses stay responsive and maintain operational efficiency in a competitive marketplace.