In the evolving landscape of garment production, efficiency and precision are paramount. But what is digital printing in textiles, and how does it reshape the way businesses approach manufacturing? Simply put, digital textile printing is an inkjet-based method that prints designs directly onto fabric or transfer media. Unlike traditional screen printing, it eliminates the need for physical screens, allowing for high-resolution graphics, unlimited colors, and significantly faster turnaround times.

For B2B providers and apparel brands, adopting a professional digital textile printer is no longer just an option—it is a competitive necessity.

The Versatility of the DTF Textile Printer

One of the most disruptive technologies in this sector is the DTF textile printer (Direct-to-Film). This process involves printing a design onto a specialized PET film, applying a hot-melt adhesive powder, and transferring it to the fabric using a heat press. The primary advantage of DTF technology is its unmatched versatility. While traditional methods or even DTG (Direct-to-Garment) may struggle with certain materials, a high-quality DTF system works seamlessly on:

Cotton and Polyester: Perfect for hoodies and activewear.

Blends and Synthetic Fibers: Ideal for specialized uniforms.

Dark and Light Fabrics:** Ensuring vibrant color reproduction regardless of the base.

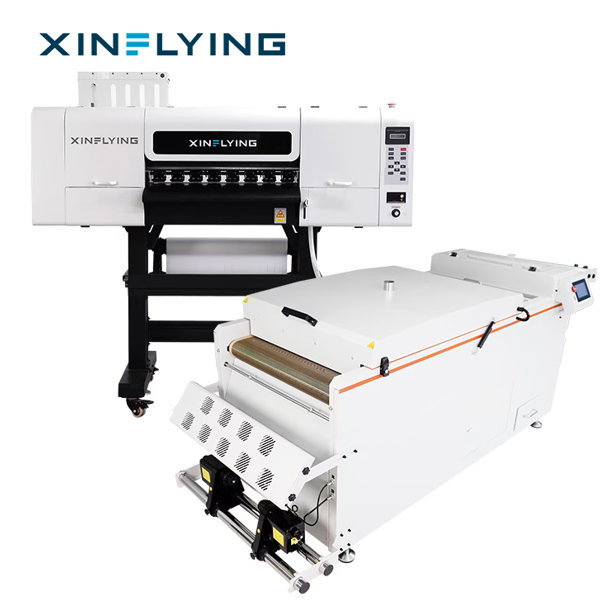

Scaling with Xinflying Technology

As a leading manufacturer, Xinflying provides industrial-grade solutions designed for high-volume production. Their flagship models, such as the C604+H6501 24-inch DTF Printer, are engineered for businesses looking to scale. Key specifications of Xinflying’s professional lineup include:

Precision Printheads: Equipped with 4pcs Epson i3200-A1 printheads for stable, high-speed output.

Productivity: Capable of reaching speeds up to 27m²/h (4-pass mode), ensuring bulk orders are met with ease.

Advanced Features: Built-in white ink circulation and an integrated auto-shaker system to minimize manual labor and prevent nozzle clogging.

By integrating these advanced digital solutions, textile businesses can reduce waste, lower setup costs, and deliver the intricate, durable prints that modern consumers demand. Whether you are a startup or a large-scale distributor, digital textile printing offers the agility needed to thrive in today’s on-demand market.