As the global poultry industry continues to scale up, feed manufacturers are under constant pressure to produce high-quality feed efficiently and consistently. For farms focusing on layer production, the challenge lies in balancing output capacity, pellet quality, and nutritional precision. Selecting a reliable poultry feed making machine plays a vital role in meeting these demands, as it determines both production efficiency and the nutritional consistency of the final feed.

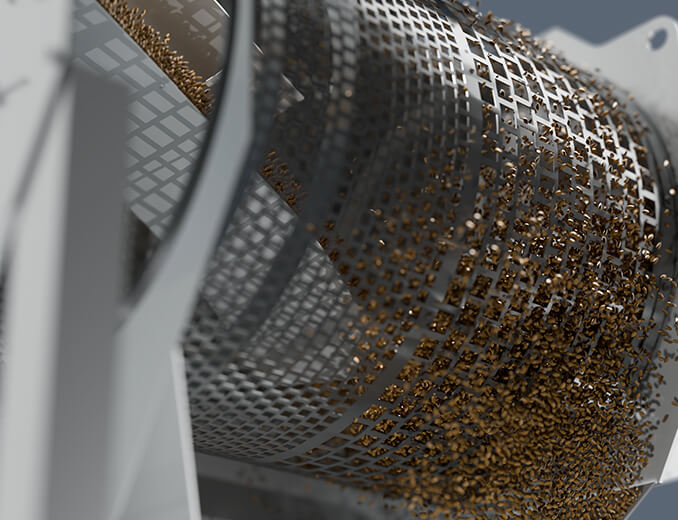

A poultry feed making machine designed for large-scale layer feed production must integrate stability, precision, and intelligent control. High-capacity pellet machines typically operate continuously for extended hours, so their structure and transmission systems need to be durable and efficient. Gear-driven systems, stainless-steel conditioners, and advanced die designs contribute to the machine’s ability to produce uniform pellets at a consistent rate. Uniformity is crucial because consistent pellet size ensures even nutrient distribution, which directly supports optimal egg production and flock health.

Essential Elements of High-Capacity Layer Feed Production

One of the most important features of an efficient pellet machine is its ability to maintain energy efficiency without compromising quality. Energy consumption accounts for a major portion of operational costs, especially in large-scale facilities. Modern feed production systems address this challenge through intelligent monitoring and optimized steam conditioning. By maintaining precise temperature and moisture levels during the conditioning process, the machine enhances starch gelatinization and nutrient absorption, resulting in better pellet quality and feed digestibility.

Another key factor is machine automation and control. Automated systems can monitor temperature, pressure, and motor load, allowing operators to make real-time adjustments that stabilize production and prevent feed loss. Smart interfaces also make it easier to manage production data, track performance, and reduce downtime. When these technological innovations are combined, they contribute to smoother operations and more predictable output — essential for maintaining consistent quality in layer feed production.

Engineering Innovations that Improve Reliability and Output

Modern pellet machines also integrate features that simplify operation and maintenance. For example, quick-change die systems and modular designs reduce service time and enable faster adjustments for different feed formulations. Advanced cooling and drying systems help improve pellet durability and reduce breakage during storage and transportation, ensuring that the final feed reaches the farm in excellent condition.

Additionally, the choice of materials used in machine construction influences its longevity and performance. Heavy-duty stainless steel, anti-corrosion coatings, and reinforced components ensure that the equipment remains stable under continuous use. These engineering details help manufacturers achieve higher productivity with lower maintenance costs — a balance that is essential for long-term profitability.

Conclusion: Sustainable Efficiency Through Proven Solutions

Efficient layer feed production requires the integration of robust machinery, intelligent systems, and deep industry expertise. Through years of innovation and engineering excellence, FAMSUN has developed a range of solutions that address the complex demands of modern poultry operations. Their layer feed systems are designed to ensure consistent output, reduce energy consumption, and maintain nutritional balance across every batch. With their advanced technologies and global experience, FAMSUN continues to help feed manufacturers worldwide achieve sustainable growth, improved efficiency, and reliable high-capacity feed production for the future.